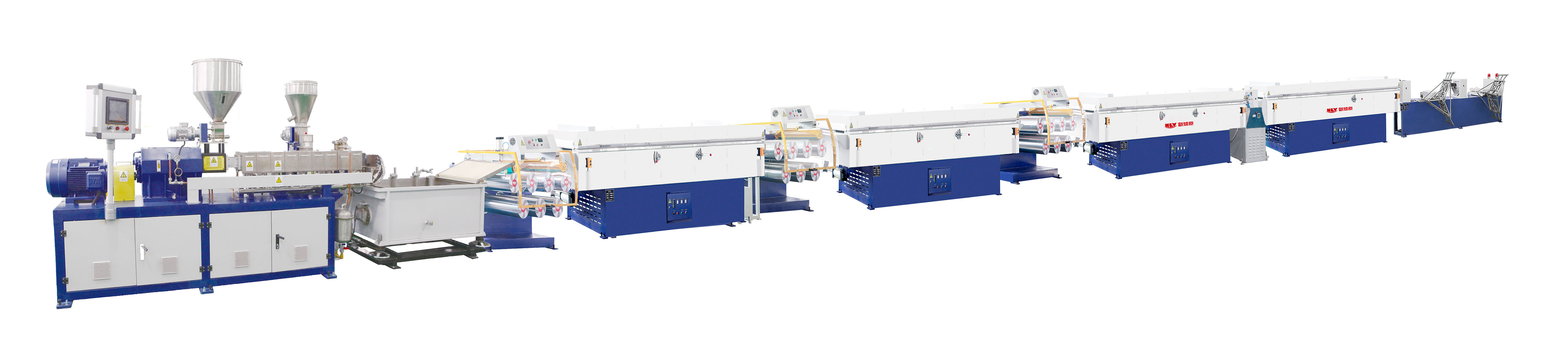

abrasive brush extrusion machine

Detailed Product Description

Applications:workplace deburring, grinding and polishing of the surfaces of steel, wooden,stone, textile, hardware, circuit board, TFT and other materials.

| Item | Abrasive Monofilament Extrusion Machine |

| Raw Material | PA6, PA610, PA612 |

| Dia. of monofilament | 0.1-0.35mm; 0.35-1.0mm |

| Dia. of screw | 45mm×2 |

| Holes of spinneret | pcs |

| Heating type of spinneret | oil heating, electrical heating |

| Stretching mode | hot water, hot wind |

| Qty. of stretching unit | 1-4 |

| System installed capacity | 350KW |

| Normal operational capacity | 210KW |

| Overall size(L×W×H) | (40-52m)x 2.8m x 3m |

| Total weight | 25-36T |

*These data just for reference, exact specs depend on final configuration

▶Features

1.Extruder

Two seperate components feeder.

Special design screw.

Automatic adjustment screw speed.

Extruder with automatic pressure feedback system to accurately control the output.

PID intelligent temperature control.

independent heating system.

Unique flow channel ensure each yarn running without interference.

Helical gear transmission system with oil bath lubrication reduce the maintenance times and cost.

AC Motor complete with AC inverter Drive.

All driving rollers with Hard Chromim plated.

Ceramics plate also available. It have better anti-corrosion ability.

Excellent insulated treatment help saving energy and cost

Patented air flow designed to ensure consistent temperature and evenly heat distrubution.

Doulbe layer oven also available which can heat and stretch the yarn in all around.

PID Temperature controller.

Various Types can satisfy customers' demands.

Linear guideway to control the alternate motion.

▶Service & Advantage

1. Provide the most advanced industry solution.

2. Free consulting for layout of new workshop.

3. Running and test with feeding material before delivery.

4. Could provide the trainning service for your new workers.

5. Could provide the 24 hours video service.