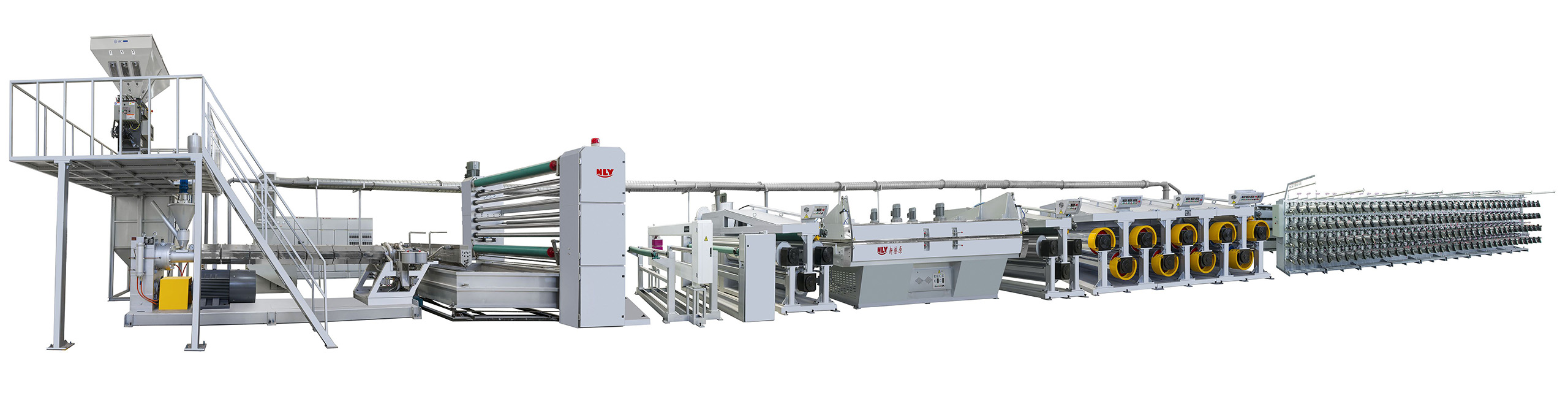

carpet backing tape extrusion line

Detailed Product Description

▶Features

★ Using 3+1 position dosing system

★ Melt pressure on-line inspection and display digital intelligently

★ Automatic double layer screen exchangeer

★ The cooling water tank has water constant stabilizer

★ Use X-ray to inspect the thickness of film on line and record all data

★ Rotary knife stand with 5 kinds of knife for continuous using

★ Double layer oven is opened by double cylinder which makes the structure more fluent

★ Specially designed passage, making hot wind distribute evenly

★ Hard chromium plating heating roller can reach 250 degree sets the yarn perfectly

★ High quality reciprocated screw with critically process

★ European standard safeguard system

▶Technical parameter

| Item | SJPL-D110×33-1100×2 | SJPL-D120×33-1500 ×2 |

| Max extrusion volume | 580kg/h | 650kg/h |

| Screw Diameter | 110mm | 120mm |

| Ratio of L/D | 33:1 | 33:1 |

| Rotation speed of screw | 20-120r/min | 20-120r/min |

| Length of mold lip | 1100mm(double lips) | 1500mm(double lips) |

| Max production speed | 280m/min | 280m/min |

| Flat yarn fibre scope | 60-200tex | 60-200tex |

| Drawing ratio | 4-10 | 4-10 |

| No.of winder | 352Spindles | 480Spindles |

| System installed capacity | 430kw | 500kw |

| System normal operational capacity(about) | 258kw | 300kw |

| Overall dimension(L×W×H) | 43000×3830×2700mm | 50000×3900×2800mm |

| Total weight | 35T | 40T |

▶Service & Advantage

1. Provide the most advanced industry solution.

2. Free consulting for layout of new workshop.

3. Running and test with feeding material before delivery.

4. Could provide the trainning service for your new workers.

5. Could provide the 24 hours video service.